The Durability of Metal and Plastic Legend Plates in Harsh Industrial Applications

When operating in tough environments, the material you use for control panel legend plates makes all the difference in long-lasting durability.

Posted on 06/06/2023

The Durability of Metal and Plastic Legend Plates in Harsh Industrial Applications

In the vast landscape of industrial environments, where machinery, equipment, and systems often operate under extreme conditions, legend plates play a crucial role in conveying information and ensuring efficient, safe operation.

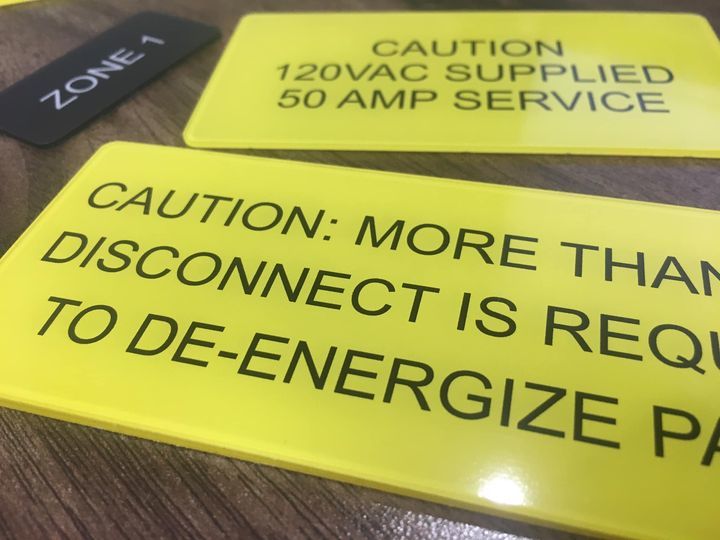

Legend plates, typically made of metal or plastic, provide clear and durable labeling for control panels, toggle switches, push buttons, and other various instruments.

This article explores and compares how different types of metal and plastic legend plates withstand the challenges posed by tough industrial settings.

Metal Legend Plates

Metal legend plates are used for their strength and ability to endure demanding industrial environments that contain chemicals, moisture, extreme temperatures, UV rays and more. They are typically made of the strongest and most durable metals such as stainless steel, anodized aluminum, or brass.

The top qualities of metal legend plates include:

1.Better Durability: Metal plates are highly resistant to impact, abrasion, and extreme temperatures daily. They can withstand harsh weather conditions, corrosive chemicals, and physical stress, making them suitable for heavy-duty industrial applications over an extended period.

2.Enhanced Chemical Resistance: Metal legend plates provide excellent resistance to chemicals, including harsh solvents and cleaning agents commonly found in industrial applications. This resistance ensures that the labels remain intact and legible, ensuring safety and efficiency for the long run.

3.Heightened UV Stability: Metal is a great choice to withstand prolonged exposure to ultraviolet (UV) radiation without fading or degradation. This feature makes them ideal for outdoor applications or environments with strong UV exposure from the sun or other bright lighting.

4. Improved Longevity: Metal legend plates have a longer lifespan compared to plastic. They resist fading, cracking, and peeling, ensuring that the labels remain visible and functional for an extended period.

Plastic Legend Plates

Plastic legend plates offer a more cost-effective alternative to metal plates, catering to a wide range of light industrial applications where the exposure to harsh chemicals or other environmental issues aren’t as severe.

Top characteristics of plastic legend plates include:

1. More Versatility: Plastic plates are available in various materials, including acrylic, tamper-evident vinyl, and PVC. Each material offers specific advantages such as flexibility, impact resistance, or temperature tolerance, allowing for customization based on the application's requirements.

2. Lightweight: Plastic plates are significantly lighter than metal plates, making them easier to handle and install. This characteristic is particularly useful when labeling portable or handheld devices.

3. Design Flexibility: Plastic plates offer greater design flexibility, allowing for more intricate graphics, logos, barcodes, or color schemes to be incorporated into them. This customization can enhance visual clarity and improve the overall aesthetic appeal.

4. Moisture Resistance: Acrylic legend plates exhibit excellent moisture resistance, protecting the labels from humidity, water splashes, and condensation. This resistance helps maintain the visibility and longevity of the legend plates.

Considerations for Both Types of Legend Plates

While metal and plastic legend plates have their unique qualities, there are some common considerations to keep in mind for any industrial application:

1. Adhesive Backers: Both metal and plastic plates should have reliable adhesive backing to ensure secure attachment to equipment and control panels. The adhesive should withstand high temperatures, chemicals, and vibrations to maintain label integrity.

2. Legibility: The labels must be clear, easy to read, and resistant to fading. Using high-contrast colors and fonts, as well as employing techniques like laser engraving or thermo-enhanced screen printing, can improve visibility and durability.

3. Environmental Factors: Industrial environments often expose legend plates to extreme temperatures, moisture, vibrations, harsh chemicals, and potential impact. Choosing materials and designs that can withstand these factors is crucial for long-lasting performance.

Which is Right for Your Application?

In the realm of harsh industrial environments, both metal and plastic legend plates have their advantages and can withstand the challenges they face.

Metal plates offer exceptional durability, chemical resistance, and longevity, while plastic plates provide versatility, lightweight design, and customization options.

Choosing the right legend plate material depends on the specific requirements of your application and the environmental conditions in which they will be used.

Nap Tags Has the Answer!

We invite you to talk with your team of tag experts to discuss your specifications, and we can help you make the best choice.

Call or email us and we’ll be happy to share our knowledge and provide you with a price quote on the custom legend plates that best suit your application.